Gyroscope 25IRIG-Mod.2

Description

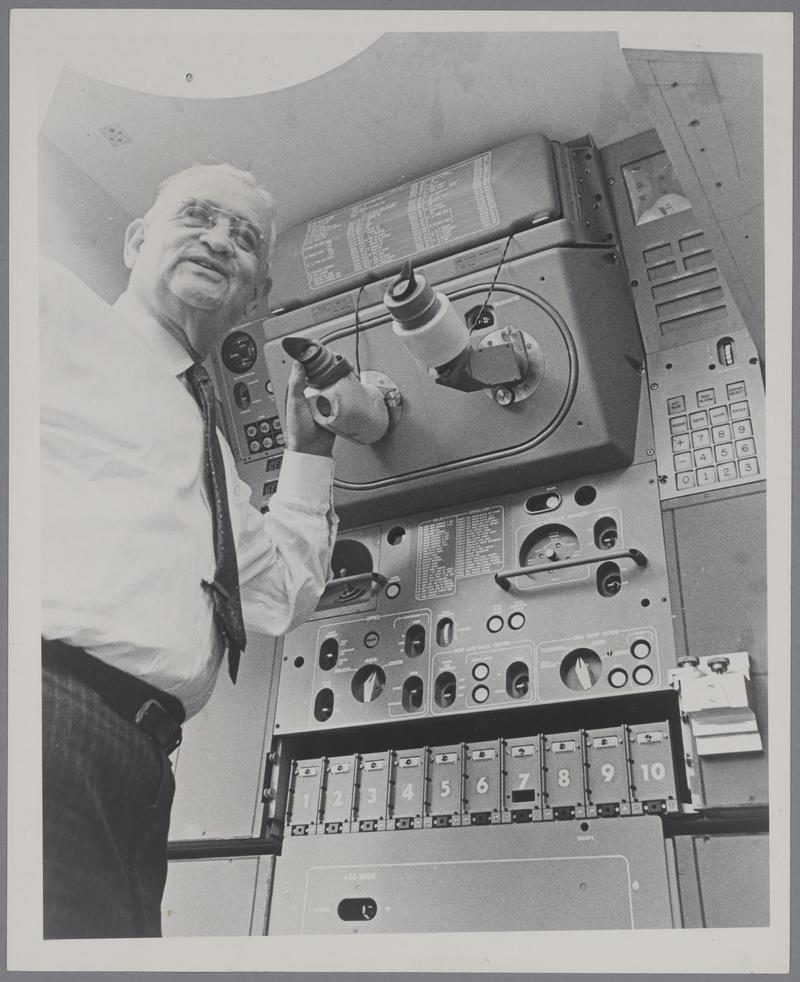

Unit no. 74 C. Navy, Polaris MK.2/Apollo This type of gyroscope was developed for the U.S. Navy's Polaris submarine-launched ballistic missile and the Apollo guidance systems. It was designed by the MIT Instrumentation Laboratory and manufactured by the AC Spark Plug Division of General Motors in Milwaukee, Wisconsin. This particular gyroscope is an Apollo I IRIG was was used in the Block I Guidance and Navigation (G&N) system. (The Apollo II IRIG, was used in the Block II Command Module and Lunar Module lunar mission configurations.)

The history of the Apollo version is based on the NASA Technical Note D-8227, "Apollo Experience Report - Guidance and Control Systems: Primary Guidance, Navigation, and Control System Development" by M.D. Holley et al, May 1976. (https://www.ibiblio.org/apollo/Documents/TN-8227-ApolloExperienceReport-PGNCS.pdf)

"Selection of MIT as the prime G&N contractor made the selection of an MIT-designed byro probable. Because early mission-error analyses indicated performance compatibility, the MIT system proposal was based on the use of the Polaris system; and, because the Polaris procurement had been reasonabley successful, the Polaris Mark II model 25 IRIG was selected as the Apollo gyro. Certain changes were made in adapting the Polaris instrument for the Apollo application. The torque generator was changed from a two-winding, current-product torquer to a single-winding, current-squared torquer to provide a more efficient computer torqueing interface. Torque generator and signal generator excitation frequencies were changed from 4800 and 800 hertz, respectively, to 3200 hertz to match the computer timing-pulse frequency." (p. 45)

"Of all the manufacturing and technological problems that were encountered in the 8-year span of the development and manufacture of the Apollo PGNCS, the IRIG ball bearing problem was the most persistent and was the last to yield to solutions." (p. 45) The assumption of all involved was that the gyroscope was adquate for the task so no attention was given to the IRIG bearing design. That proved problematic. In this particular instance, money was not the derminative factor as bearing sets from a few hundred dollars to almost $1,000 were used. the NASA report authors noted in 1976: "From 1962 until the time of publication of this report, more than $20 million has been spent on the Apollo IRIG, and the high failure rate of the bearing assembly has been the leading gyro problem." (p. 46)

"The Apollo I IRIG is a single-degree-of-freedom, floated, integrating gyro. The wheel assembly is supported by a pair of preloaded, angular-contact (R-2 size) ball bearings, adjusted to achieve an isoelastic structure having equal compliance along the spin and output axes. The wheel assembley is driven by a two-phase, synchronous, hysteresis motor of 28 volts at 800 hertz. The wheel is enclosed in a sealed, spherical beryllium float." (See pages 47-48 for a full description of the gyroscope.)

Related organizations